According to the performance of the covering glue, it can be divided into ordinary type, heat-resistant type, flame-retardant type, cold-resistant type, acid-alkali-resistant type, oil-resistant type, etc.

Trough Conveyor Belt

According to the performance of the covering glue, it can be divided into ordinary type, heat-resistant type, flame-retardant type, cold-resistant type, acid-alkali-resistant type, oil-resistant type, etc.

Product Details

Technical Parameters

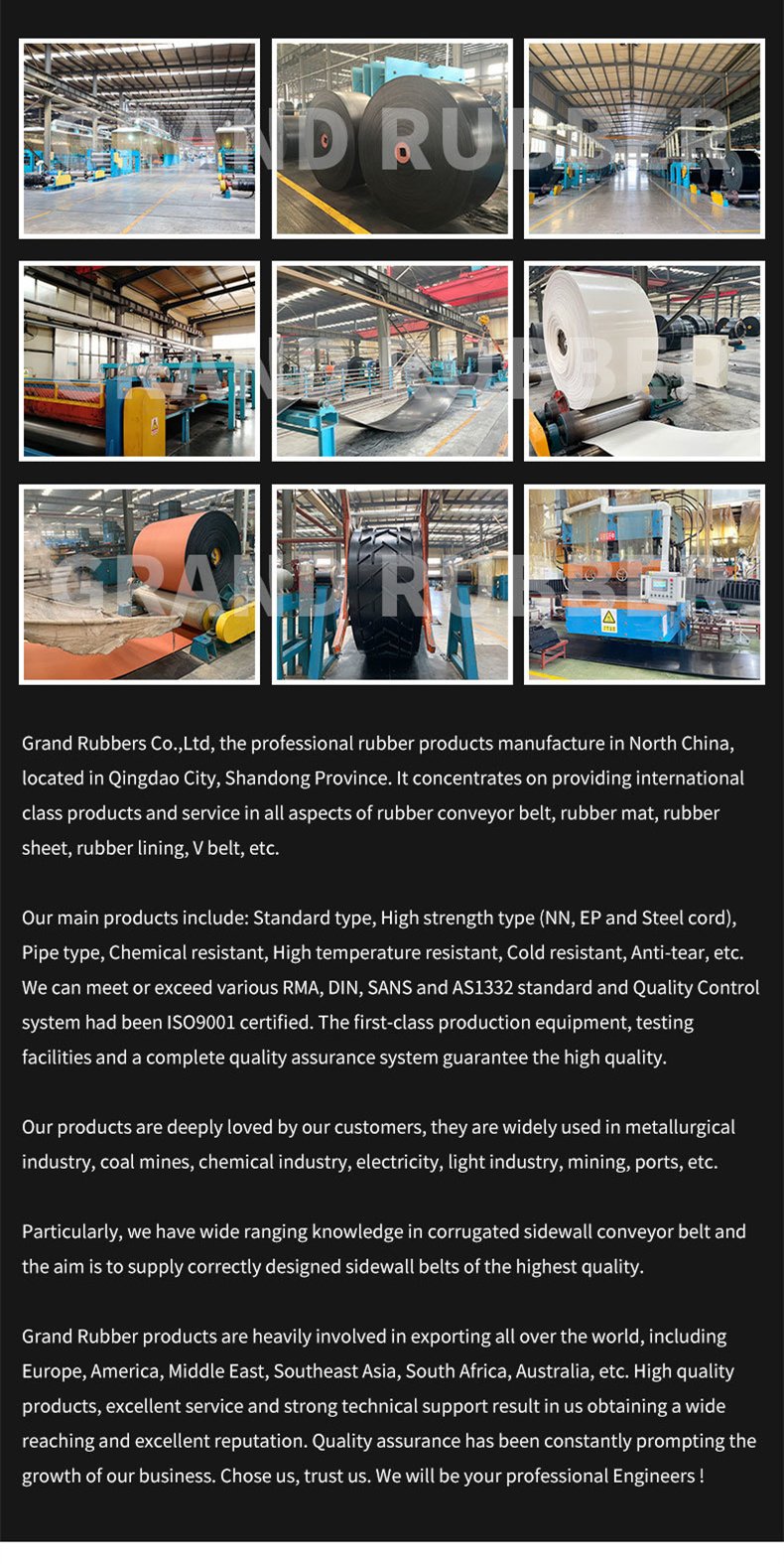

Company Overview

Product Classification

According to the performance of the covering glue, it can be divided into ordinary type, heat-resistant type, flame-retardant type, cold-resistant type, acid-alkali-resistant type, oil-resistant type, etc.

Product Structure

It is composed of three parts: the base belt, the sidewall, and the cleats. The sidewall prevents the material from slipping and falling, and the function of the cleat is to support the material. In order to realize the sidewall belt transportation, the T-type TC type is usually used. The sidewall and cleats are connected to the base belt by secondary vulcanization, which has high connection strength.

Product Features

The incline conveyor belt has a large conveying inclination angle, up to 90°. It is widely used in mines, coal mines, electric power, docks, and other conveying and loading places. It can convey bulk, granular and powdery materials. It is a large conveying angle and occupies an area It is a high-energy-saving conveying carrier with a small area, no turning point, reduced civil investment, and low maintenance cost.

Product Use

It is widely used in the transportation of materials in the fields of ports, metallurgy, mining, electric power, coal, casting, building materials, food, and chemical industries. It can make all kinds of bulk materials be continuously conveyed at an arbitrary inclination angle of 0-90 degrees. It has the characteristics of large conveying inclination, wide use range, small area, no turning point, reduced civil construction investment, low maintenance cost, and large conveying volume.

Sidewall Range

The sidewall design ensures maximum flexing without fatigue, the profile has excellent vertical stability for load retention and return side support. The design allows for high compression to ensure smooth inner deflection around small radii. Another important design feature is that the sidewalls can be pressed form both sides when being applied to the base belt, this offers much higher bond strengths and security. The fabric insertion is of the diagonal type which gives excellent tear resistance and also allows the sidewall to flex more easily.

Main Rubber Types

Normal Standard High Abrasion Resistant

Moderate Oil Resistant

Heat Resistant to 150℃

High Heat Resistant to 180℃

Flame Retardant

Other qualities may be available to special order, please contact us.

Executive Standard

China GB/T7984 Standard

Germany DIN22102 Standard

US RMA Standard

UK EN ISO15236 Standard

Japan JISK6322 Standard

Australia AS1332 Standard

Type | H (mm) | BW (mm) | TW (mm) | P (mm) | Weight(kg/m) | Min Pulley Din(mm) |

S | 40 | 30 | 20 | 25 | 0.58 | 125 |

60 | 50 | 45 | 40 | 1.55 | 160

| |

80 | 50 | 45 | 40 | 1.82 | 200 | |

100 | 50 | 45 | 40 | 2.20 | 250 | |

120 | 50 | 45 | 40 | 2.65 | 315 | |

MDSF | 120 | 75 | 70 | 63.2 | 3.20 | 315 |

160 | 75 | 70 | 63.2 | 4.76 | 400 | |

200 | 75 | 70 | 63.2 | 6.45 | 500 | |

240 | 75 | 70 | 63.2 | 7.50 | 630 | |

250 | 75 | 70 | 63.2 | 6.37 | 630 | |

280 | 75 | 70 | 63.2 | 8.90 | 800 | |

300 | 75 | 70 | 63.2 | 9.33 | 800 | |

HHDF | 300 | 100 | 90 | 83 | 12.10 | 800 |

400 | 100 | 90 | 83 | 18.72 | 1000 | |

500 | 100 | 90 | 83 | 16.80 | 1250 |

*Our sidewalls type MDSF 120mm and higher have special diagonal fabric reinforcement in the corrugations as standard, but smaller sidewalls can have this feature where required.

*The above pulley diameter is limited to ordinary grade and standard coating rubber thickness. When the special grade of coating rubber and strength are different, a larger pulley diameter may be required. Please consult for specific specifications.

Cleat Range

When the conveying angle is less than 40 degrees, the cleat is generally T type; when the conveying angle is greater than 40 degrees, the cleat is generally C type, TC type or TCS type. The fine adjustment of the cleat distance needs to consider the correspondence with the sidewall wave crest, and the side bolt fastening device matched with different types of cleats can prevent materials from leaking from the gap between the cleats and unloading to cause accumulation of dead ends.

Cleat Type | Height(mm) | Base Width(mm) | Weight(Kg/m) | Min Pulley Dia(mm) |

C | 55 | 75 | 1.60 | 125 |

75 | 90 | 1.90 | 150 | |

90 | 110 | 2.50 | 250 | |

110 | 110 | 2.60 | 315 | |

T | 40 | 70 | 0.78 | 125 |

55 | 80 | 1.50 | 125 | |

75 | 100 | 1.65 | 150 | |

90 | 110 | 2.50 | 250 | |

110 | 105 | 2.63 | 315 | |

140 | 110 | 3.50 | 400 | |

180 | 110 | 4.70 | 500 | |

TC | 75 | 85 | 2.10 | 150 |

90 | 110 | 2.95 | 250 | |

110 | 110 | 3.68 | 315 | |

140 | 150 | 5.94 | 400 | |

180 | 148 | 7.20 | 500 | |

230 | 157 | 9.30 | 630 | |

280 | 160 | 13.45 | 800 | |

TCS | 230 | 105 | 9.55 | 630 |

280 | 105 | 15.40 | 800 | |

360 | 200 | 22.80 | 1000 | |

470 | 200 | 23.30 | 1250 |

*Our cleats form 110mm and higher have special diagonal fabric reinforcement in the vertical and angled parts, but smaller cleats can have this feature when required.

FAQ

Q1. How about your experience?

We have mainly produced rubber conveyor belts for over 20 years.

Q2. What are your main products?

Multi-ply fabric conveyor belt(EP/NN type), steel cord conveyor belt, chevron conveyor belt, sidewall belt, white conveyor belt, bucket elevator belt, filter belt, and special conveyor belts with the characteristics of heat resistant, cold resistant, oil resistant, flame retardant, abrasion resistant, etc.

Q3. What about the lead time?

1) 3--5 days for sample.

2) 20--25 days for mass production. If urgent, we have the green channel.

Q4. Can you send free samples?

Yes, we provide samples for free after inquiry.

Q5. How about the package?

Standard export packing method, your special requirement will be respected.

Q6. What are your Payment terms?

T/T or L/C.

Q7. Can you do door-to-door?

No problem.

Q8. How do you ensure your product quality?

Our quality control system had been ISO9001 certified. The first-class production equipment, testing facilities, and a complete quality assurance system guarantee high quality.

Q9. What is your major market?

Our products are heavily involved in exporting all over the world, including Europe, America, the Middle East, Southeast Asia, South Africa, Australia, etc.

Q10. What you can do to support me better?

We can provide products that meet quality standards, timely delivery, transportation packaging requirements, and customers' other special requirements.

Reviews

When I had an issue with my HiYue Ice machine, their support team was on it immediately. The international warranty and responsive service made the entire process hassle-free. It's rare to find such dedication to customer satisfaction.

When I had an issue with my HiYue Ice machine, their support team was on it immediately. The international warranty and responsive service made the entire process hassle-free. It's rare to find such dedication to customer satisfaction.

When I had an issue with my HiYue Ice machine, their support team was on it immediately. The international warranty and responsive service made the entire process hassle-free. It's rare to find such dedication to customer satisfaction.

Write a review

Inquiry Now