What is Incline Belting

Incline belting refers to the use of conveyor belts that are designed to transport materials up inclined surfaces or steep slopes. Incline belting is commonly used in industries such as mining, construction, agriculture, and waste management, as it enables the efficient movement of materials over sloped terrain.

Product Features

The conveyor belts used for incline belting are designed with special features like chevron patterns or cleats, which provide increased traction and prevent materials from slipping or spilling during transportation. These incline belts are designed to prevent or reduce slide-back on inclines. Chevron and Steepclimb belting also increase conveyor capacity by quick pick up at the point of loading. Ideal for granular materials such as wet sand and gravel.

Product Use

Incline belting is used in high-incline environments, utilizing cover textures and vulcanized profiles to keep transported materials secure while in motion. With an array of different compounds available for fabrication, incline belts can be implemented with virtually any application.Incline belting systems can be customized according to the specific needs and requirements of each industry, and can range from small, portable systems to large, heavy-duty systems for mining and construction applications.

Executive Standard

China GB/T7984 Standard

Germany DIN22102 Standard

US RMA Standard

UK EN ISO15236 Standard

Japan JISK6322 Standard

Australia AS1332 Standard

Main Technical Parameters

Belt | PVC Belt with baffle, with 2sides skirt walls to |

Size | 2000incline+500flat mm L*500mm W*200-2000H |

Stainless steel Hopper | with bottom hopper for feeding |

Structure Material | Aluminium, (304 stainless steel , steel for options) |

Motor | 750W (or as your required) |

Running speed | 1-10m/min (or as your required) |

Voltage | 110V/220V/380V/480V |

Foot Cup /Casters | shock proof quality |

Shipping | BY SEA, BY AIR, BY EXPRESS |

Weight-bearing | 10-200 KGS |

packing | inner with water-proof film, outer by woodcase |

Warranty period | 1 year |

Inspection | provide photo and video for confirm before shipping |

Lead time | 3-4 days |

FAQ

Q1. How about your experience?

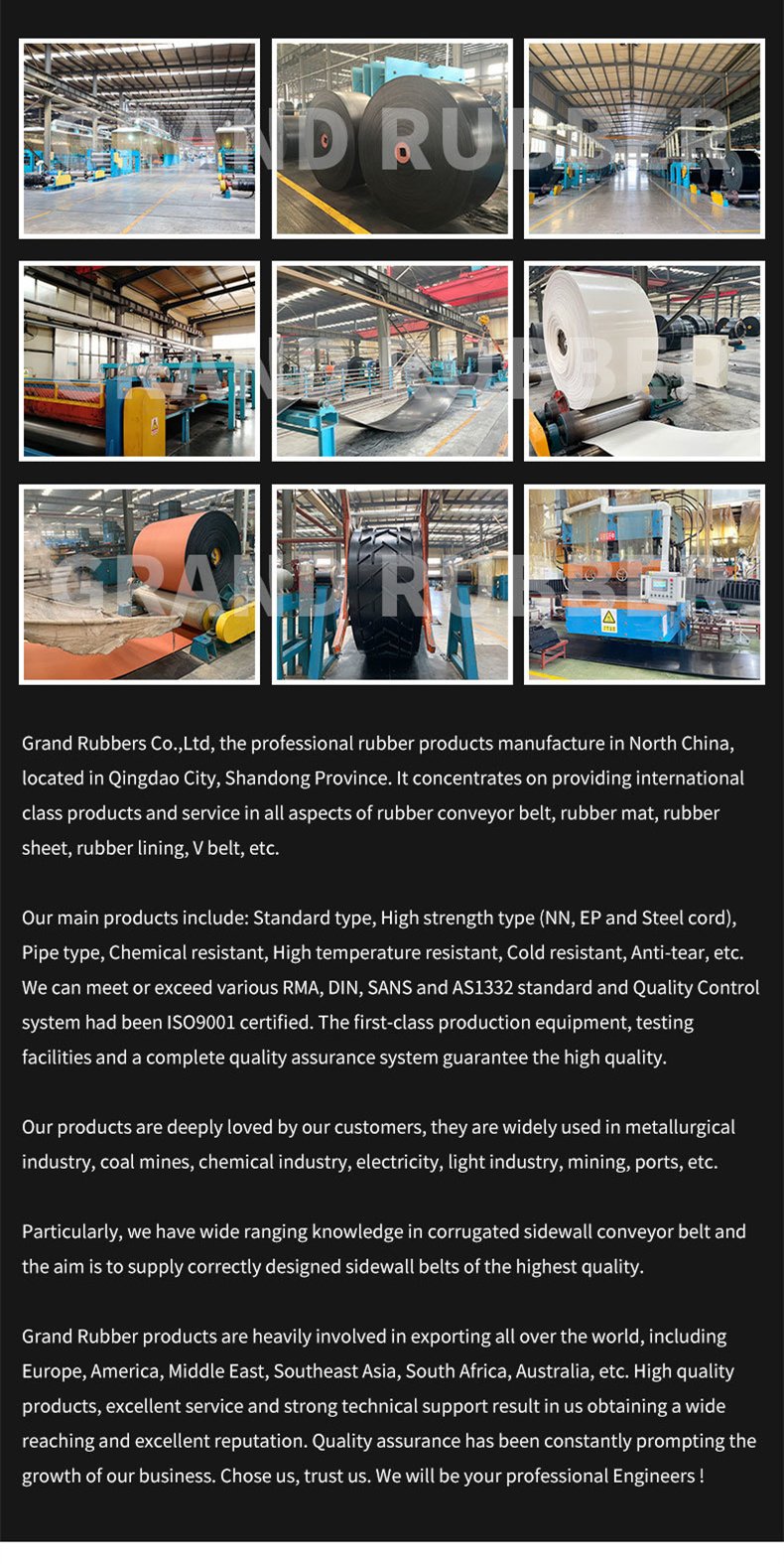

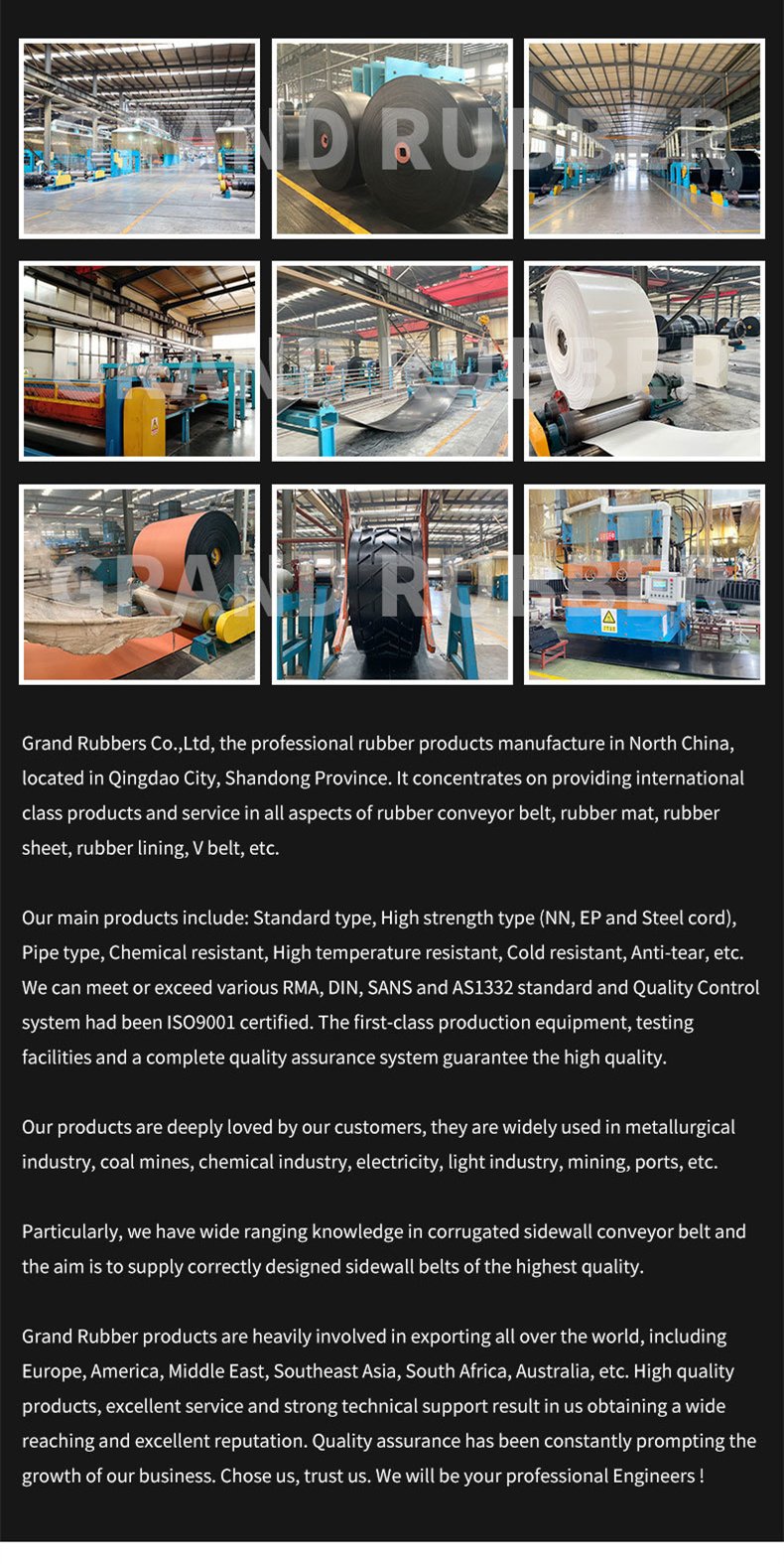

We have mainly produced rubber conveyor belts for over 20 years.

Q2. What are your main products?

Multi-ply fabric conveyor belt(EP/NN type), steel cord conveyor belt, chevron conveyor belt, sidewall belt, white conveyor belt, bucket elevator belt, filter belt, and special conveyor belts with the characteristics of heat resistant, cold resistant, oil resistant, flame retardant, abrasion resistant, etc.

Q3. What about the lead time?

1) 3--5 days for sample.

2) 20--25 days for mass production. If urgent, we have the green channel.

Q4. Can you send free samples?

Yes, we provide samples for free after inquiry.

Q5. How about the package?

Standard export packing method, your special requirement will be respected.

Q6. What are your Payment terms?

T/T or L/C.

Q7. Can you do door-to-door?

No problem.

Q8. How do you ensure your product quality?

Our quality control system had been ISO9001 certified. The first-class production equipment, testing facilities, and a complete quality assurance system guarantee high quality.

Q9. What is your major market?

Our products are heavily involved in exporting all over the world, including Europe, America, the Middle East, Southeast Asia, South Africa, Australia, etc.

Q10. What you can do to support me better?

We can provide products that meet quality standards, timely delivery, transportation packaging requirements, and customers' other special requirements.