What is Standard Application ST Belts

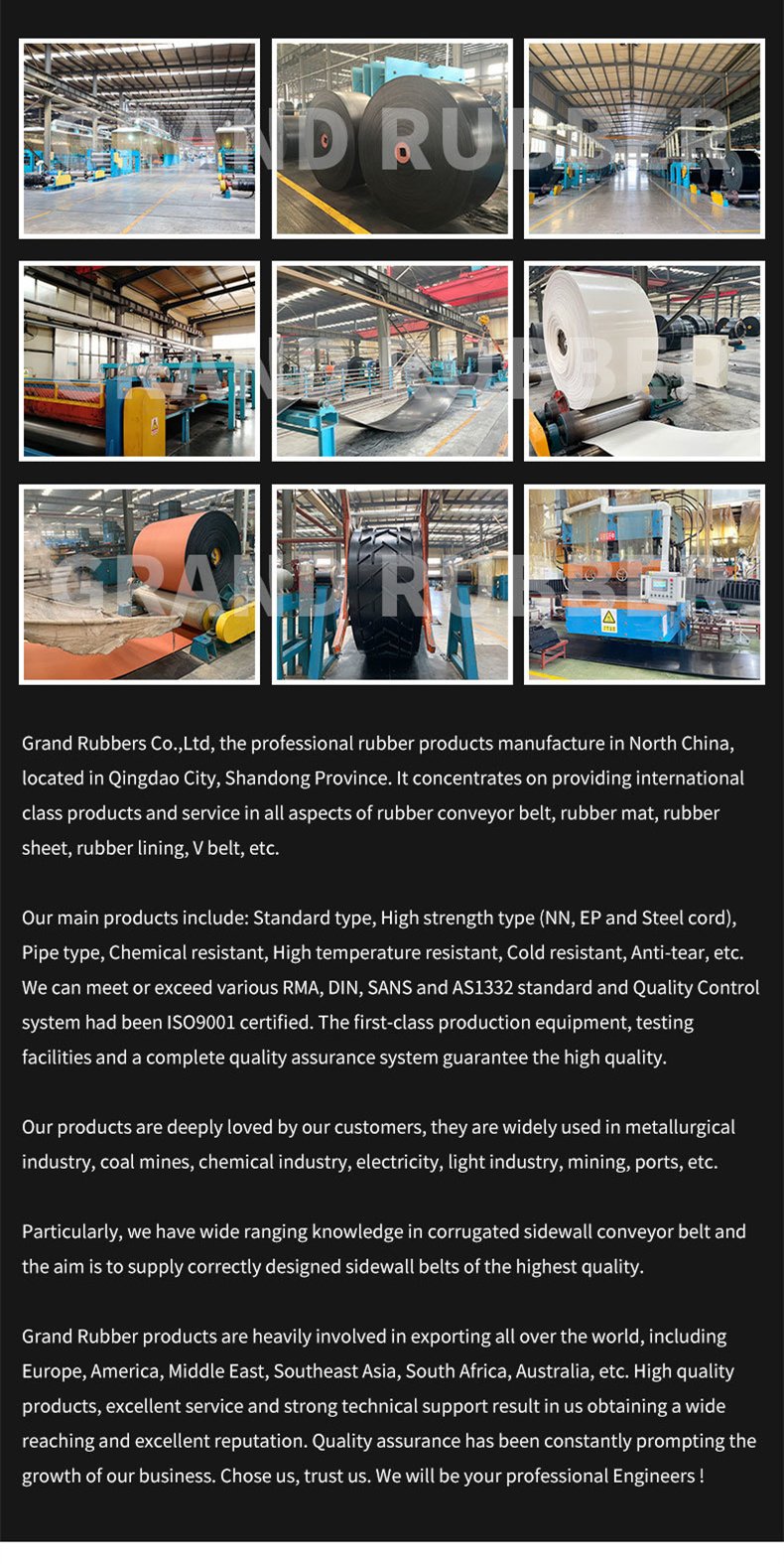

ST belts are a type of synchronous timing belts used in various applications, such as industrial machinery, conveyor systems, and automotive engines. They have teeth on the inner surface that mesh with corresponding pulleys, providing precise and efficient power transmission. ST belts are known for their high performance, durability, and resistance to wear and tear, making them suitable for heavy-duty applications. They come in various widths, lengths, and materials to meet specific requirements, and are designed to operate in harsh environments and at high speeds.

Product Features

1. High strength: ST belts are made from high-quality materials that offer exceptional strength and durability, making them reliable for long-term use.

2. Precise power transmission: The teeth on the inner surface of the ST belt ensure precise power transmission by meshing with corresponding pulleys.

3. Low noise: ST belts operate quietly due to their tooth design and are ideal for applications where noise levels need to be kept to a minimum.

4. Low maintenance: ST belts require low maintenance and have a long service life, so they are suitable for use in applications where regular replacement of belts is not feasible.

5. Resistance to wear and tear: ST belts are designed to withstand wear and tear, even in harsh operating environments, due to their unique tooth design and material properties.

Product Use

1. Industrial machinery: ST belts are commonly used in industrial machinery such as conveyor systems, packaging equipment, and printing presses.

2. Automotive industry: ST belts are used in engines to drive camshafts and other components, as well as in power steering and timing systems.

3. Agriculture: ST belts are used in agricultural machinery such as tractors, harvesters, and balers. 4. Medical equipment: ST belts are used in medical equipment such as dental drills, dialysis machines, and CT scanners.