What is EP Textile conveyor belt

The EP textile is short for Polyester fabric, which includes polyester toward longitudinal(warp) and polyamide for latitude(weft), EP textile plies are sandwiched between rubber skim coats for adhesion and load support. Bottom and top cover compounds are added for maximum protection of the belt carcass. The EP conveyor belt consisting of two to six EP fabric plies, EP rubber conveyor belt has the same merit as Nylon conveyor belt.

Product Features

EP fabric also has excellent compatibility with other rubbers, so it can be combined with any type of cover grade to make it a perfect match for almost any application. This allows EP conveyor belt to convey basically any type of product in any environment, from fine powders to large lumps, from dry to greasy materials, from extremely cold to very hot conditions.

A.Lower longitudinal elongation.

B.Full resistance to mildew, moisture and rotting.

C.Good flexibility and trough ability.

D.Short take-up lengths.

E.Suitable for middle and long-distance transportation of higher load and speed.

Product Use

EP textile conveyor belt is widely used by the mining and processing industries for transporting bulk or lumpy materials such as quarrying, ore, coke, aggregates, crops, sand, clinker, chemicals, construction materials, etc.

Executive Standard

China GB/T7984 Standard

Germany DIN22102 Standard

US RMA Standard

UK EN ISO15236 Standard

Japan JISK6322 Standard

Australia AS1332 Standard

Main Technical Parameters

Test Item | EP100 | EP125 | EP150 | EP200 | EP250 | EP300 | EP350 | EP400 |

warp | weft | warp | weft | warp | weft | warp | weft | warp | weft | warp | weft | warp | weft | warp | weft |

Breaking strength (N/cm) | ≥1350 | ≥550 | ≥1600 | ≥650 | ≥1900 | ≥750 | ≥2350 | ≥785 | ≥3000 | ≥800 | ≥3400 | ≥800 | ≥3900 | ≥750 | ≥4500 | ≥900 |

Breaking elongation (%) | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 | ≥14.0 | ≤45.0 |

Elongation at 10% load (%) | ≤1.5 |

| ≤1.5 |

| ≤1.5 |

| ≤1.5 |

| ≤1.5 |

| ≤1.5 |

| ≤1.5 |

| ≤1.5 |

|

Heat shrinkage (150℃, 30Min.) | ≤5.0 | ≤1.0 | ≤5.0 | ≤1.0 | ≤5.0 | ≤1.0 | ≤5.0 | ≤1.0 | ≤6.0 | ≤1.0 | ≤6.0 | ≤1.0 | ≤6.0 | ≤1.0 | ≤6.0 | ≤1.0 |

Adhesion (N/2.5cm) | ≥196.0 | ≥196.0 | ≥196.0 | ≥196.0 | ≥196.0 | ≥196.0 | ≥196.0 | ≥196.0 |

FAQ

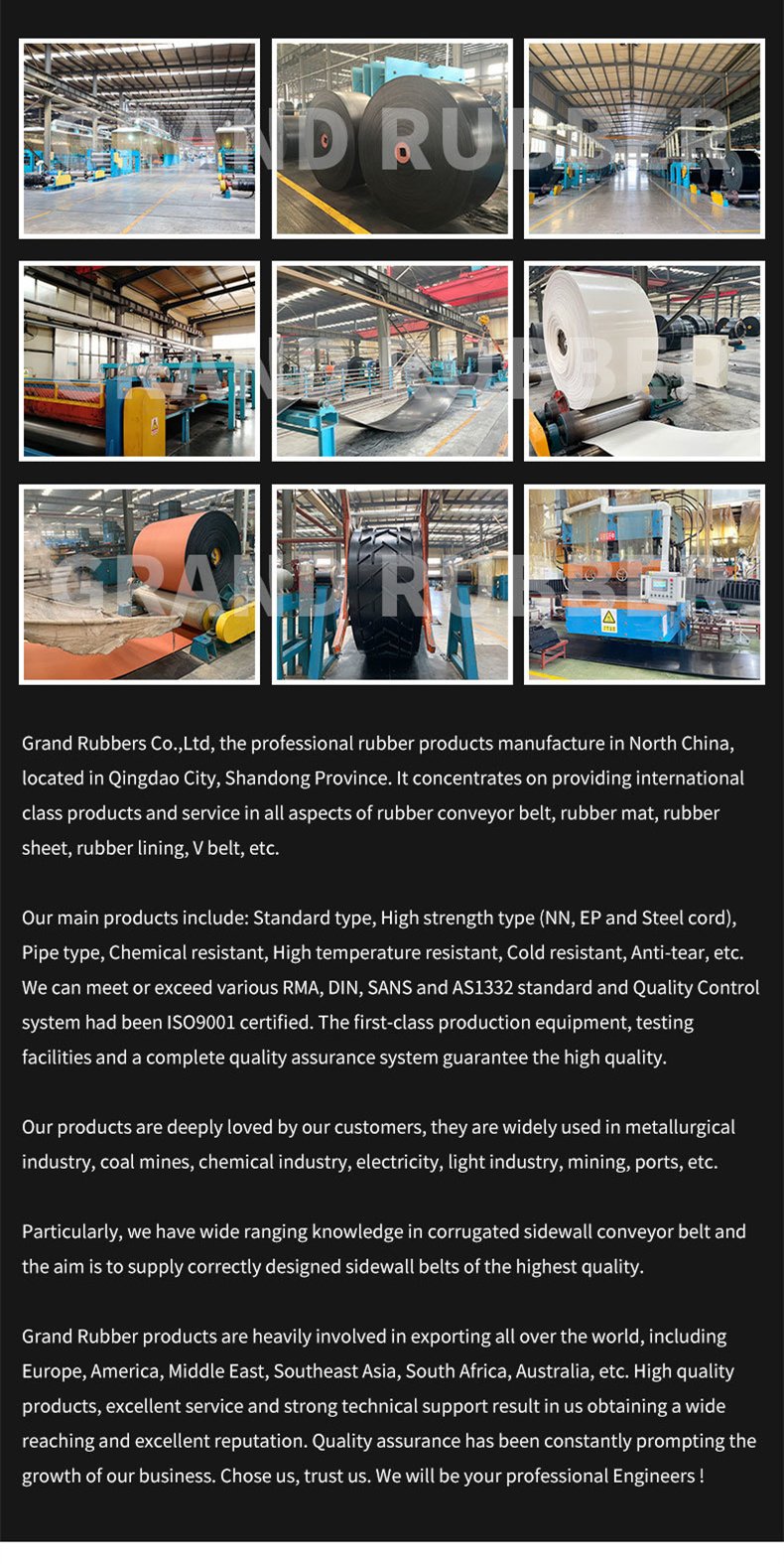

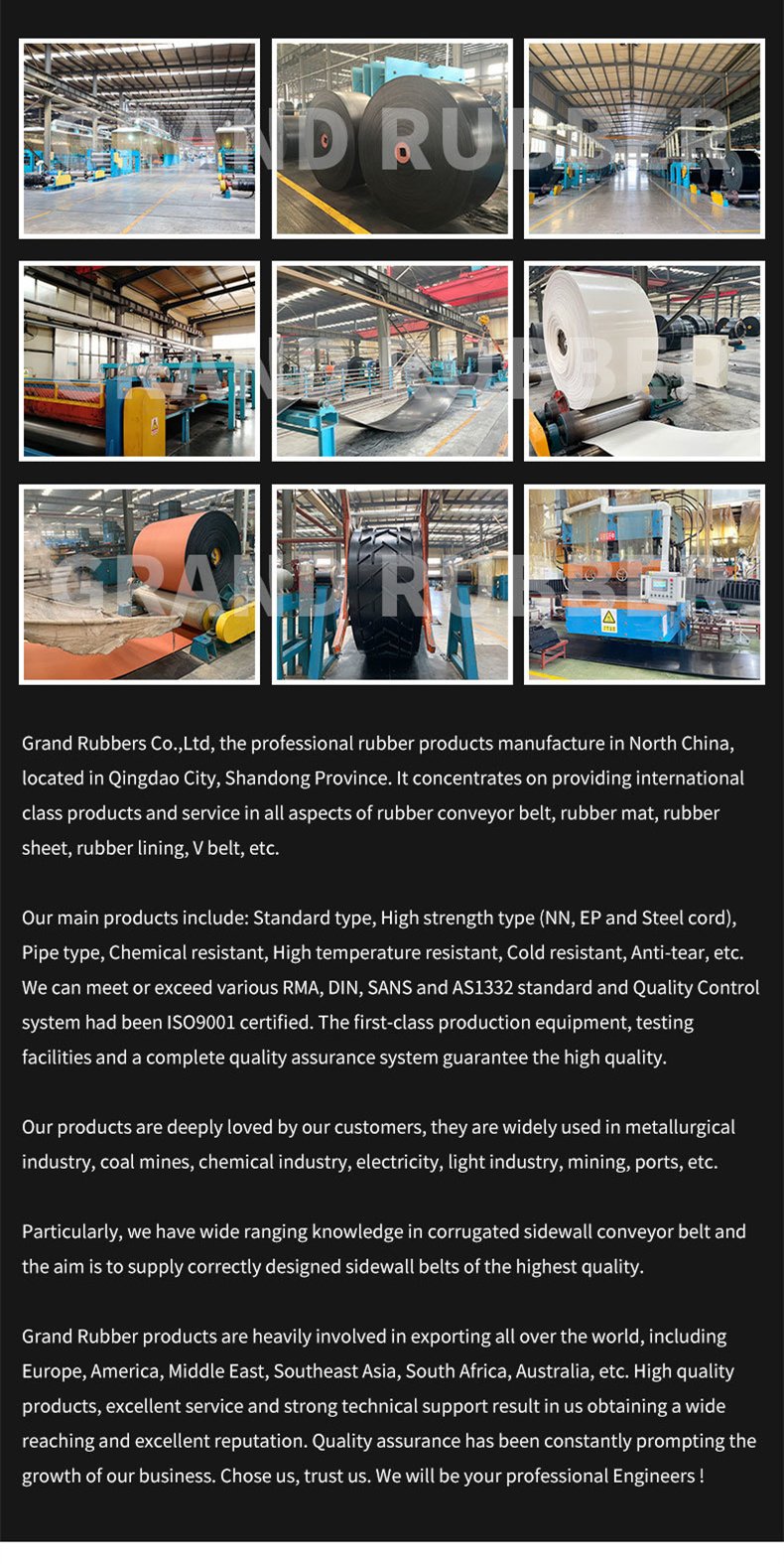

Q1. How about your experience?

We have mainly produced rubber conveyor belts for over 20 years.

Q2. What are your main products?

Multi-ply fabric conveyor belt(EP/NN type), steel cord conveyor belt, chevron conveyor belt, sidewall belt, white conveyor belt, bucket elevator belt, filter belt, and special conveyor belts with the characteristics of heat resistant, cold resistant, oil resistant, flame retardant, abrasion resistant, etc.

Q3. What about the lead time?

1) 3--5 days for sample.

2) 20--25 days for mass production. If urgent, we have the green channel.

Q4. Can you send free samples?

Yes, we provide samples for free after inquiry.

Q5. How about the package?

Standard export packing method, your special requirement will be respected.

Q6. What are your Payment terms?

T/T or L/C.

Q7. Can you do door-to-door?

No problem.

Q8. How do you ensure your product quality?

Our quality control system had been ISO9001 certified. The first-class production equipment, testing facilities, and a complete quality assurance system guarantee high quality.

Q9. What is your major market?

Our products are heavily involved in exporting all over the world, including Europe, America, the Middle East, Southeast Asia, South Africa, Australia, etc.

Q10. What you can do to support me better?

We can provide products that meet quality standards, timely delivery, transportation packaging requirements, and customers' other special requirements.