90°large angle lifting system advantages

1. Smaller floor space:

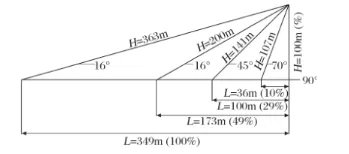

For the same lifting height, the floor space is smaller and the project investment is lower;

Relationship between conveyor floor space and layout angle

1. Large conveying capacity: strong continuous conveying capacity

GRAND RUBBER 90° lifting sidewall conveyor belt conveying capacity has reached up to 1760TPH;

2. Large conveying height: The vertical conveying height is constantly breaking through.

3. Wide range of use: Applicable to materials with particle size of 0-400mm;

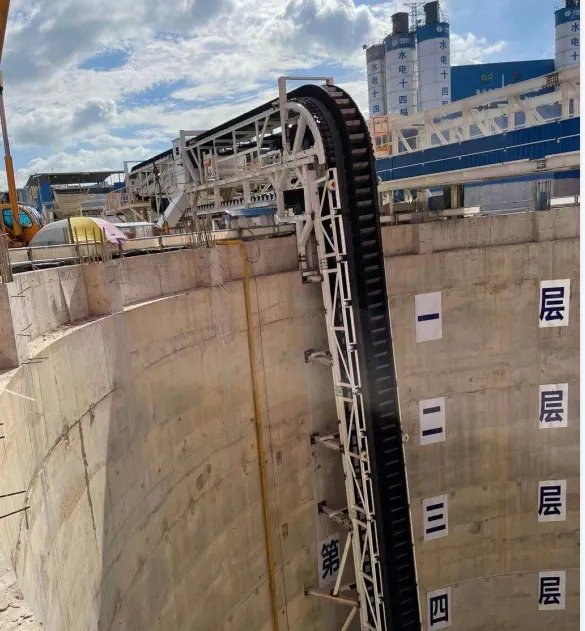

4. Easy and fast installation: The high-angle belt conveyor can be put into use after being installed on site;

5. Simple structure, easy maintenance

6. Reliable operation and reduced maintenance

7. Can reduce transfer points, lower energy consumption and more environmentally friendly

The 90°high-angle lifting and sidewall conveyor belt conveying system occupies less ground and space under the same lifting height, and has stable and high efficiency. It is increasingly valued in production and transportation. From horizontal to vertical, sidewall conveyor belt avoids the complexity of intermittent conveying and complex conveying and lifting systems, and is faster and more cost-effective.

However, in actual applications, belt conveyors often have the following problems in the 90°high-angle lifting system: belt shaking, belt slippage, vertical section material scattering, return material carrying, installation difficulties, unexpected troubleshooting and handling difficulties, which makes belt conveyor design manufacturers discouraged.

However, this technology of sidewall conveyor belt was introduced from abroad in the late 1980s and has been widely used in conveying block, granular and powdery materials, such as clinker, cement, slag, limestone, coal, grain, etc. With the rapid development of sidewall conveyor belt conveyor systems, its structure and functions have been continuously improved, upgraded and innovated, and recognized by more and more owners, becoming a new favorite in the field of bulk material conveying.

GRAND RUBBER breaks the traditional passive supporting production mode of belts, and assists owners and design manufacturers to improve the high-angle sidewall conveyor belt design and operation solutions from comprehensive aspects such as belt design and selection, conveyor key component design technology output, system diagnosis and transformation, on-site joints, installation, maintenance, etc., leading the wide application and innovation of high-angle conveying systems.

Inquiry Now